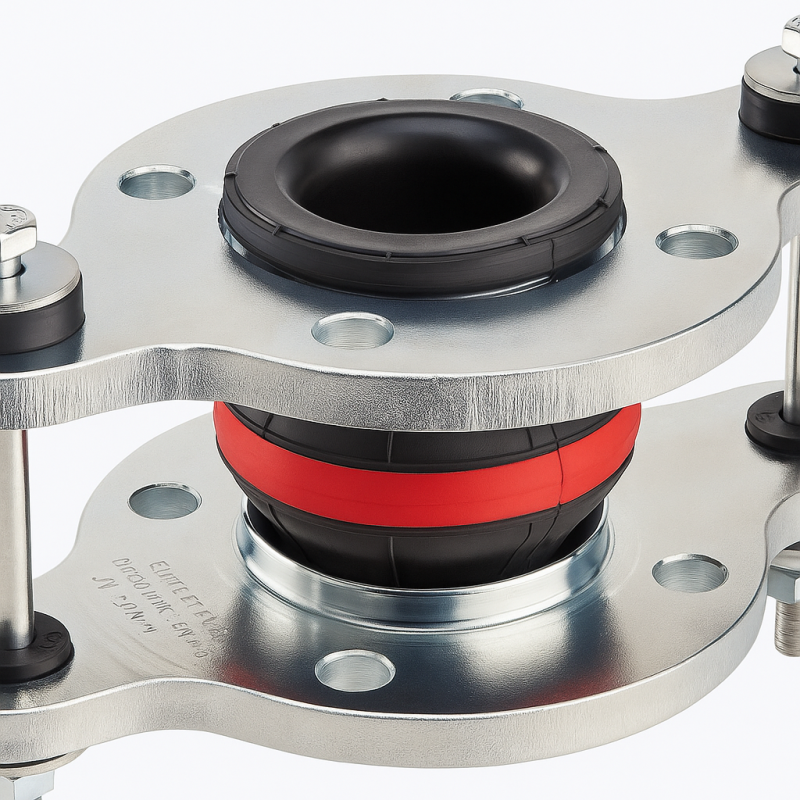

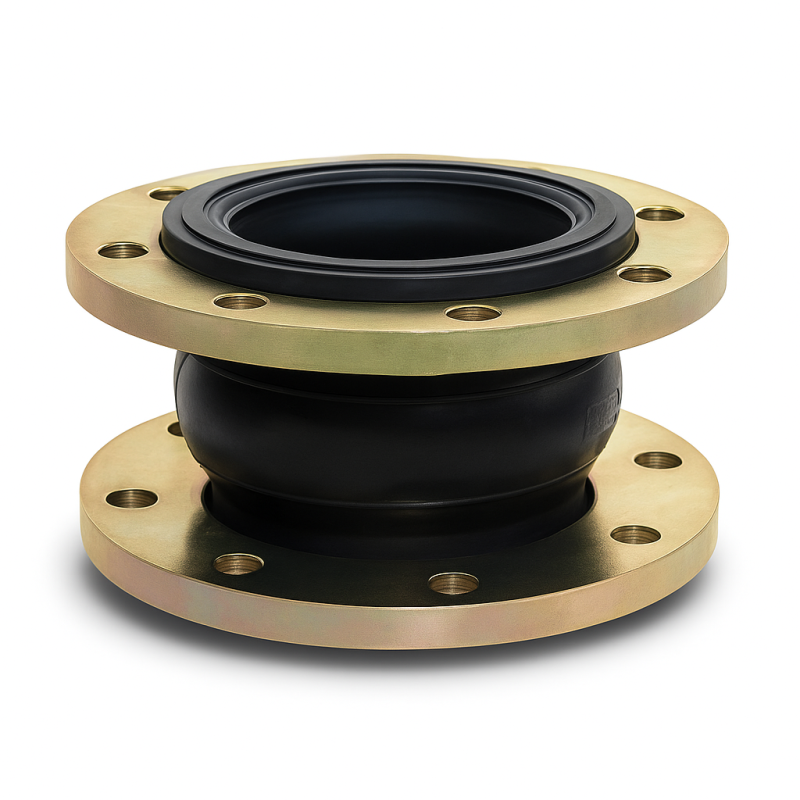

Rubber Expansion Joints

Expansion joints are generally speaking elastic components that are suitable for absorbing pipeline expansions and vibrations (e.g. due to heat, etc.) or for compensating the installation of plant components.

-

Flexibility

Very good flexibility in the axial, lateral, and angular directions.

Strain Absorption

High elongation absorption with extremely short construction lengths.

High Quality

Manufactured to the highest quality criteria - Durable and with guaranteed tightness.

Properties

Expansion joints are generally spoken \"elastic\". Components that are suitable for absorbing pipeline expansions and vibrations (e.g. due to heat, etc) or for compensating the installation of plant components. The design is decisively determined by the medium, pressure, temperature, magnitude, and direction of the expansion to be absorbed. Rubber expansion joints made of vulcanized rubber layers, which are selected according to the medium and the desired resistance, are mainly used with liquid media and high pressure. Different carrier layers such as nylon cord, aramid cord, and steel cord are available for pressure and temperature resistance.

Advantages

- Flexible (axial, lateral, angular)

- High expansion absorption with short lengths

- Excellent sound and vibration reducing effect

- Manufactured according to the highest quality criteria

- Longevity

- Guaranteed tightness

Rubber expansion joints are characterized by high flexibility in the axial, lateral and angular directions, as well as high expansion absorption with extremely short construction lengths. In addition to expansion absorption, they also have an excellent sound- and vibration-reducing effect.

RBS rubber expansion joints are manufactured according to the highest quality criteria for your specific application.

This ensures a long service life with guaranteed tightness at the same time.

Of course, we also offer all necessary accessories such as blind flanges, backing strips, screw connections, etc. Download installation instructions for RBS rubber expansion joints.

-

K. Hoffmann GmbH

For over 40 years, we have been manufacturing high-temperature-resistant boards, pressed, and milled molded parts from Vermiculite.

Due to its special properties, vermiculite is particularly suitable as a lightweight insulation material and is characterized by its temperature resistance up to 1100 °C.

If you are also looking for a sustainable insulation material without health concerns, then contact us.