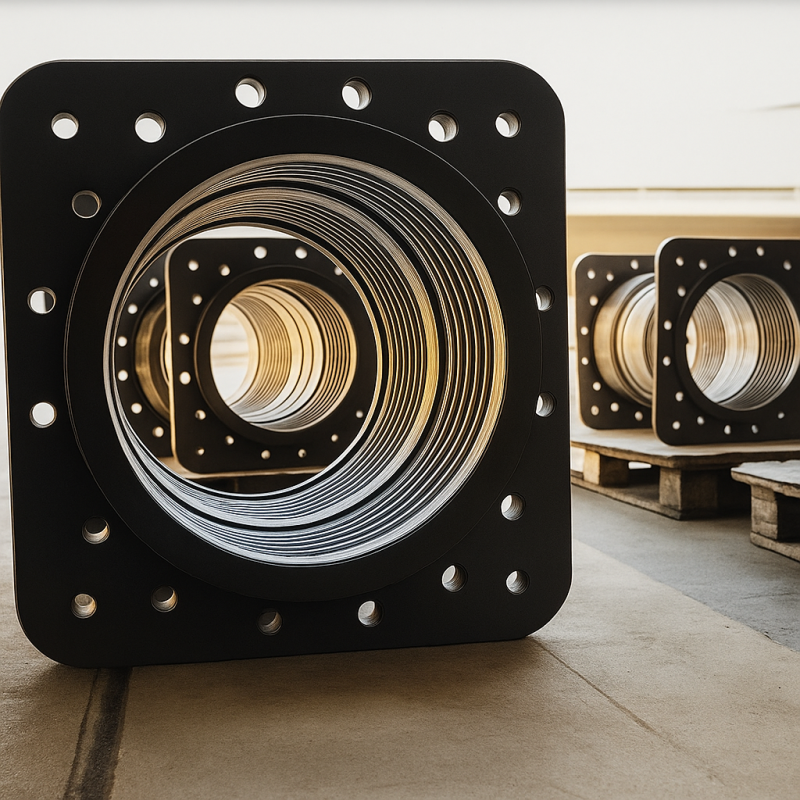

Metal Compensators and Metal Bellows

Expansion joints are generally spoken “elastic”. Components which are suitable for absorbing pipeline expansions and vibrations (e.g. due to heat, etc) or for compensating the installation of plant components.

- Steel quality

- X6CrNiMoTi17-12-2 | X6CrNiTi18-10 | 1.4301 / X5CrNi18-10 | X15CrNiSi20-12 | X8CrNiTi18-10 | S235 1.4876H

-

Аgeing resistant

Material resistant to aging and corrosion.

Flexible

Flexible, pressure-resistant, and torsion-proof.

Temperature resistant

Absorption of pipeline expansions and vibrations (e.g. due to heat).

Properties

Expansion joints are generally spoken "elastic". Components which are suitable for absorbing pipeline expansions and vibrations (e.g. due to heat, etc) or for compensating the installation of plant components. The design is decisively determined by the pumped medium, pressure, temperature, magnitude and direction of the expansion to be absorbed. RBS metal expansion joints or stainless steel expansion joints and corrugated hoses or metal bellows are used in particular for applications with high pressure. We manufacture all shapes and sizes of metal expansion joints from axial expansion joints with welding ends and flanges to cardan joint expansion joints with fixed flanges in a wide range of stainless steel qualities. Depending on the pressure, the stainless steel expansion joint can be single-walled or multi-walled. Quality is always in the foreground for us. Of course, we also offer all necessary accessories such as clamps, blind flanges, backing strips, adhesives, etc.

Advantages

- Ageing resistant

- Flexible

- Pressure resistant

- Temperature resistant

- Corrosion resistant

- Anti-twist

Steel grades

- Stainless austenitic steel 1.4571 / X6CrNiMoTi17-12-2

- Stainless austenitic steel 1.4541 / X6CrNiTi18-10

- Stainless austenitic steel 1.4301 / X5CrNi18-10

- Austenitic heat-resistant steel 1.4828 / X15CrNiSi20-12

- Austenitic heat-resistant steel 1.4878 / X8CrNiTi18-10

- Structural steel 1.0038 / S235

- High-temperature nickel-iron-chromium solid solution alloy Alloy 800 H / 1.4876H

Application

- Pipeline construction

- Chemical industry

- Iron & steel casting

- Process heat recovery

- Etc.

Download installation instructions for RBS metal expansion joints.

-

K. Hoffmann GmbH

For over 40 years, we have been manufacturing high-temperature-resistant boards, pressed, and milled molded parts from Vermiculite.

Due to its special properties, vermiculite is particularly suitable as a lightweight insulation material and is characterized by its temperature resistance up to 1100 °C.

If you are also looking for a sustainable insulation material without health concerns, then contact us.