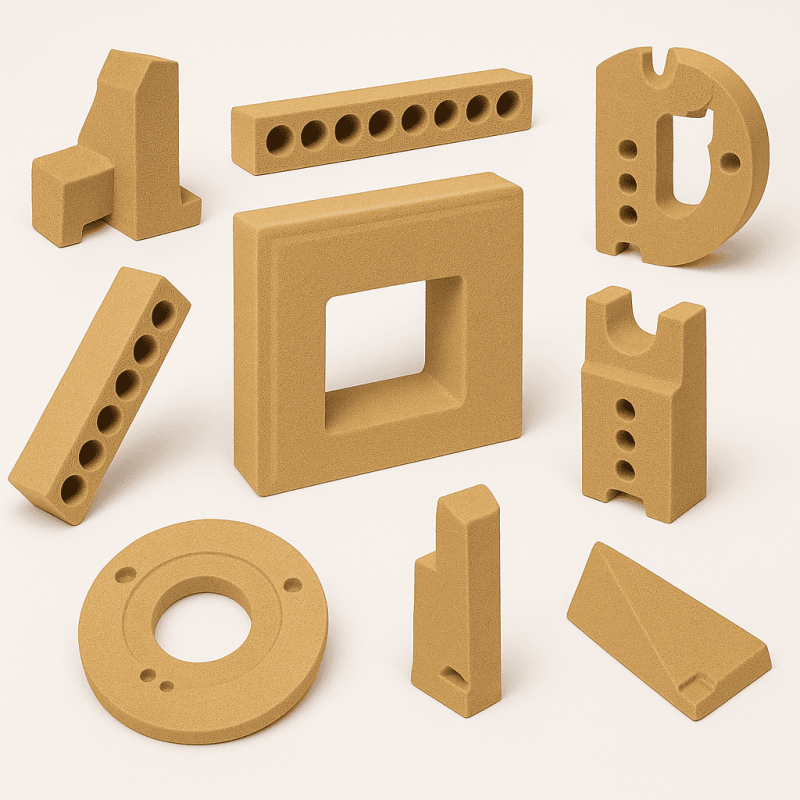

Vermiculite CNC molded parts

Vermiculite CNC molded parts – Custom-made heat-resistant precision parts

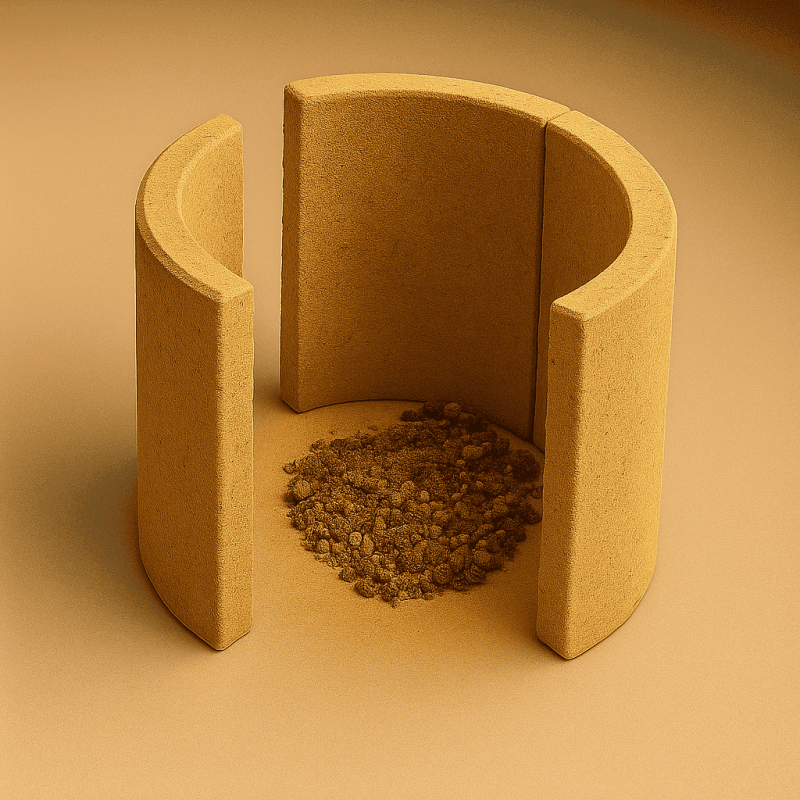

Our vermiculite CNC molded parts are the ideal solution for applications that require maximum temperature resistance, fire protection, and precise manufacturing. Thanks to modern CNC machining, we can manufacture customized molded parts from vermiculite for you – from prototypes to series projects.

Whether in furnace construction, mechanical engineering, electrical engineering, or the automotive industry: with our components, you can rely on a material that retains its properties even at temperatures above 1,000 °C.

- PRODUCT VARIATIONS

- CNC milled | CNC drilled | CNC sawn

-

Cost-oriented

Technically excellent and cost-oriented solution.

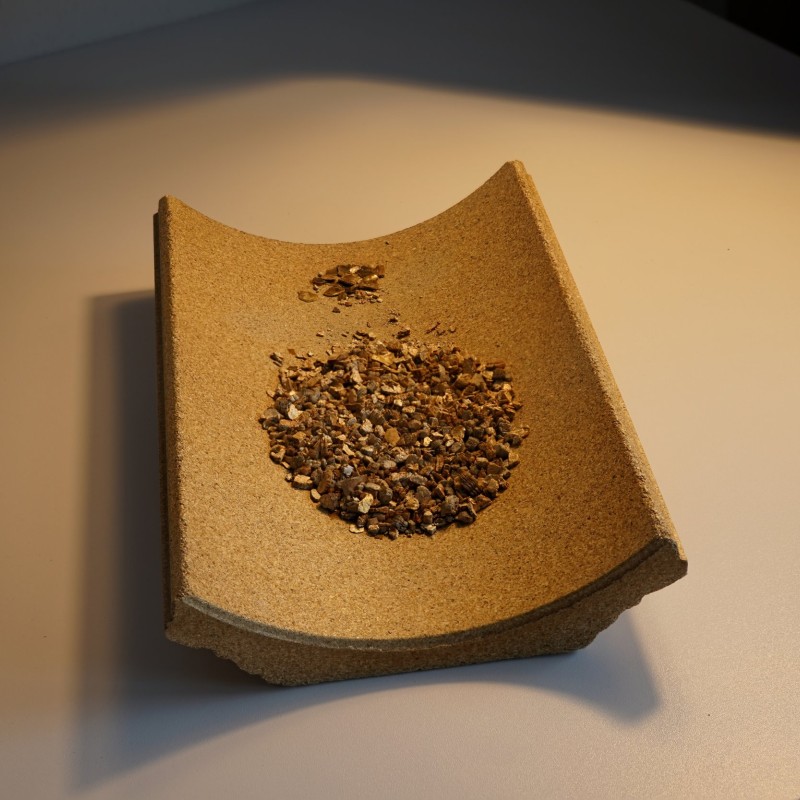

Nontoxic

Light, non-toxic, fiber-free, odorless and acid-resistant.

Refractory

Depending on the product variation, application temperatures up to 1100 ° C.

TECHNICAL DETAILS

PROPERTIES

Application Temperature 1100°C Melting point > 1300°C Panel thickness tolerance +/- 1mm Tolerance length/width +/- 2,5mm linear post-shrinkage Aprox. 1% Thermal expansion coefficient 11,0 x 10⁶ K¹ Loss on ignition 1025°C: 7% HS fare Nr. 6809.90.00 Colour Sand CHEMICAL ANALYSIS

SiO2 46,0% TiO2 0,7% Fe2O3 5,5% Al2O3 7,0% MgO 19,0% CaO 3,5% Na2O 0,2% K2O 10,0% Vermilite 375 Vermilite 475 Vermilite 600 Vermilite 700 Density 375 kg/m3 475 kg/m3 600 kg/m3 700 kg/m3 Cold compressive strength 1,3 N/mm2 2,5 N/mm2 4,2 N/mm2 4,5 N/mm2 Flexural strength 0,3 N/mm2 0,8 N/mm2 1,6 N/mm2 2,0 N/mm2 Overall porosity 85% 81% 76% 74% THERMAL CONDUCTIVITY

Temp. (W/m°K) (W/m°K) (W/m°K) (W/m°K) 200°C 0,12 0,14 0,16 0,19 400°C 0,15 0,17 0,18 0,20 600°C 0,16 0,19 0,20 0,21 800°C 0,19 0,20 0,22 0,22 Typical areas of application

Oven and fireplace construction: inserts, sealing strips, front panels

Machinery and plant engineering: insulating molded parts in welding and hardening furnaces

Electrical engineering: fire protection panels for switch cabinets and cable bushings

Aerospace: lightweight, heat-resistant components

Automotive industry: prototypes for exhaust systems or battery modules

Benefits

- Heat resistant up to 1,100 °C – perfect for applications with high thermal loads

- Non-flammable and fire-tested – maximum safety for industry and construction

- CNC-machined for maximum precision – exact contours, drill holes, chamfers, and cutouts

- Flexible in quantities – from single pieces to large series

- Sustainable and asbestos-free – safe for people and the environment

Frequently Asked Questions (FAQ)

How heat resistant are vermiculite CNC components?

Our parts withstand temperatures up to 1,100 °C, making them ideal for furnace construction, welding systems, or electrical engineering.

Are the parts available in small quantities as well?

Yes – we manufacture single pieces as well as large series. Vermiculite is particularly economical for prototypes.

Which data formats should I use for my request?

It is best to send us STEP files. PDFs are possible but require additional processing steps.

-

Downloads

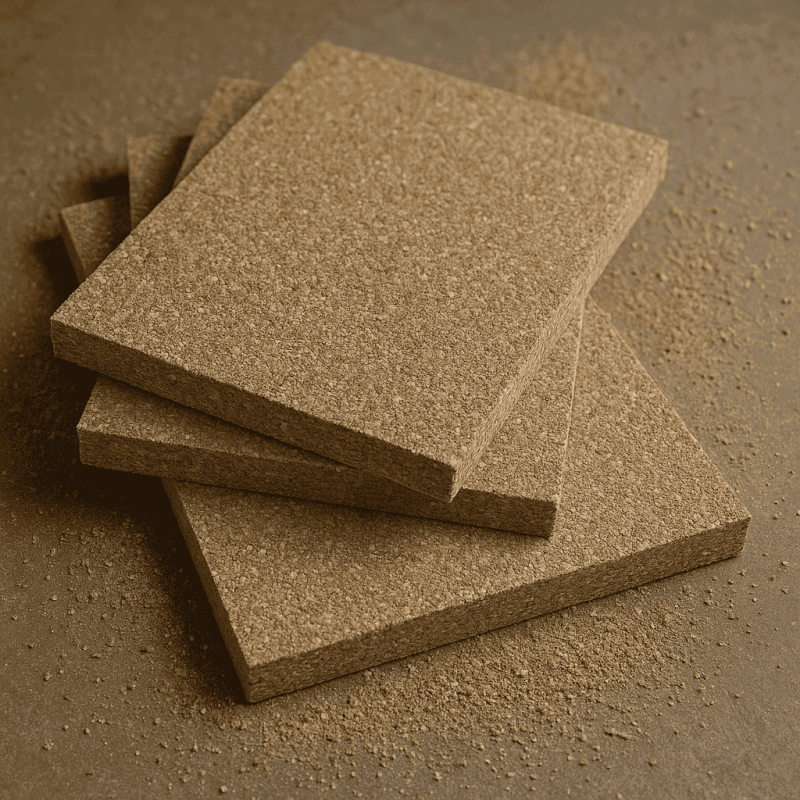

Data sheet Vermilite2000 Isolation boards

Product properties, typical applications and availabilities.

Data sheet Vermilite 2000 Isolation board RD375

Product properties, typical applications and availabilities.

Data sheet Vermilite 2000 Isolation board RD475

Product properties, typical applications and availabilities.

Data sheet Vermilite 2000 Isolation board RD600

Product properties, typical applications and availabilities.

Data sheet Vermilite 2000 Isolation board RD700

Product properties, typical applications and availabilities.

Hoffmann product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

K. Hoffmann GmbH

For over 40 years, we have been manufacturing high-temperature-resistant boards, pressed, and milled molded parts from Vermiculite.

Due to its special properties, vermiculite is particularly suitable as a lightweight insulation material and is characterized by its temperature resistance up to 1100 °C.

If you are also looking for a sustainable insulation material without health concerns, then contact us.