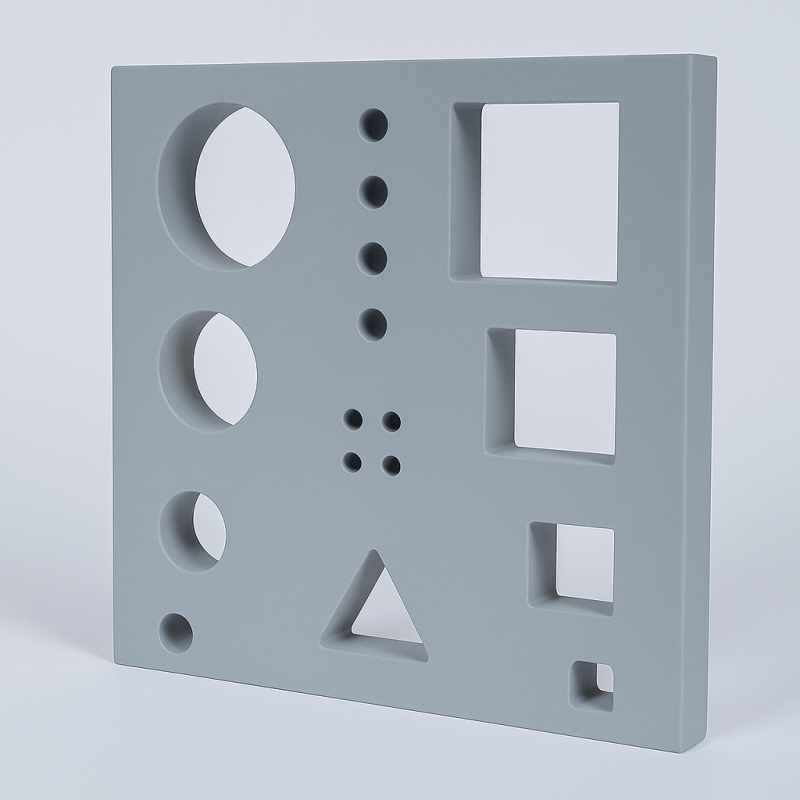

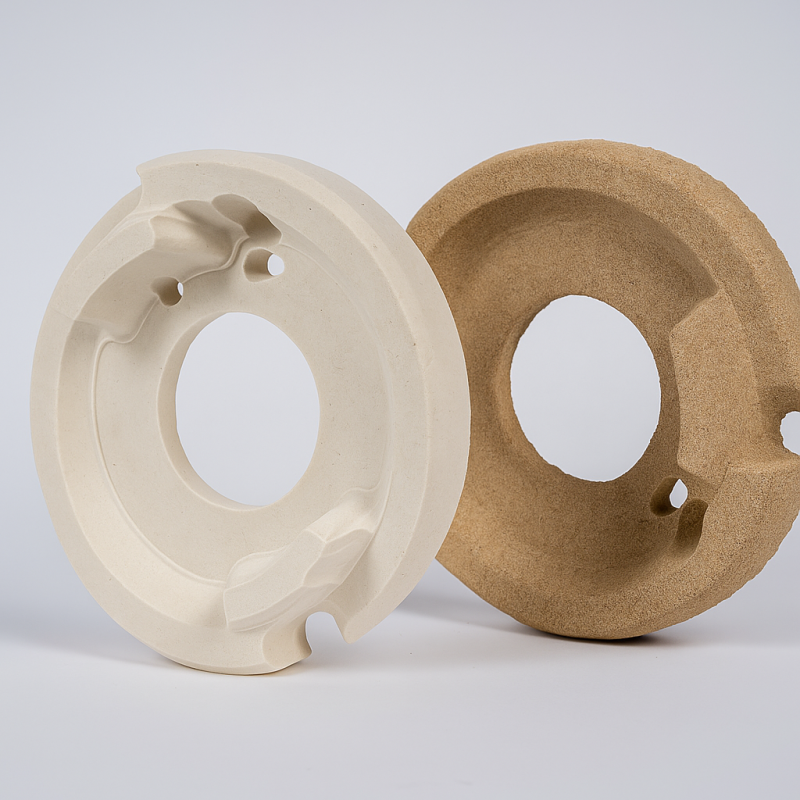

Calcium silicate mouldings

Calcium silicate mouldings maintain their dimensional stability even under extreme conditions and are suitable for temperatures up to 1100 °C.

- PRODUCT VARIATIONS

- CNC machined | CNC drilled | CNC sawn | Pressed parts according to customer specifications

-

Temperature resistance

High temperature resistance with application temperatures up to 1100°C.

Thermal conductivity

Low thermal conductivity, non-flammable and highly shock resistant.

Thermal insulation

Suitable for fire protection and thermal insulation products.

CHARACTERISTICS

Calcium silicate mouldings maintain their dimensional stability even under extreme conditions and are suitable for temperatures up to 1,100 °C. Fire protection and thermal insulation products made of calcium silicate protect people and equipment, save space and energy, and improve processes and efficiency.

The calcium silicate plates are processed into CNC milled parts or pressed parts according to customer specifications of our own production.

Benefits

- High temperature resistance

- Application temperatures up to 1100°C

- Low thermal conductivity

- Non-flammable

- Highly Shock Resistant

- Fire protection products

- Thermal insulation products

- Energy-saving

- Efficiency-enhancing

-

Downloads

Hoffmann product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

K. Hoffmann GmbH

For over 40 years, we have been manufacturing high-temperature-resistant boards, pressed, and milled molded parts from Vermiculite.

Due to its special properties, vermiculite is particularly suitable as a lightweight insulation material and is characterized by its temperature resistance up to 1100 °C.

If you are also looking for a sustainable insulation material without health concerns, then contact us.